ACT - 0001 - Fort William - TCH 139

Fort William Mk III

Inspiration

For many

people, the rugged scenery of the West Highlands of Scotland has always been an

attractive setting. It was within that region that the West Highland Railway

(WHR) was constructed from Glasgow to Fort William and with an extension on to

the small fishing port of Mallaig. The route features a variety of beautiful

scenery running across rugged moorland, around picturesque lochs and along a

rocky coastline. As a potential setting for a model railway this stunning scenery

is only part of the attraction, as the area has played host to a number of

industries and, as a result, the tracks have seen a variety of rolling stock –

both passenger and freight.

My two

previous attempts to capture the atmosphere of the WHR were built to the scale

of 4mm = 1foot, with a track gauge of 18.83mm and this Mk III version

is no exception. What makes this rendering different is that it is built within

a dedicated train room approx.3.7m x 4.2m in dimension and which is (most importantly)

dry, reasonably dustproof, fully insulated and, as a result, is cosy all year round.

Design

I wrestled

long and hard with the design of the layout and tried desperately to shoehorn a

continuous oval track into the available space, but with no luck. Firstly, it

would have meant either a lifting flap or a duck-under across the entrance –

neither of which I was keen on. Secondly, to achieve the reasonable curves

required within the confines of the space available, the mainline track became

egg-shaped, which in turn would have meant compulsory curved platforms and

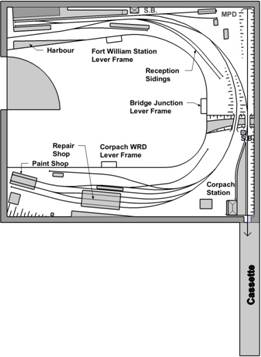

over-tight turnouts into the yards. As can be seen on the accompanying track

plan, I eventually decided to punch a hole through one wall and then locate a

cassette system out in the garage. This cassette-cum-fiddle-yard represents the

line south to Glasgow and thus allows the train room to be devoted solely to

the productive running of trains and not have any space wasted with storage

areas.

This entry

and exit to the layout from the cassette is disguised by a road overbridge spanning the small station of Corpach. Only one half of the length of the platform is

modelled; the other half pretends to be hidden by the bridge (Photo 1). This

incoming main line itself continues straight ahead, through the junction

leading to Fort William, and then disappears under another road-bridge.

However, this time it is a dummy exit, which will be explained later.

Figure 1 - A Class 156 DMU is stopping at Corpach station en route to Fort William, having entered

the layout under a road bridge marking the exit to the cassette / fiddle-yard.

As I

mentioned earlier, the prototype Fort William area plays host to a number of

rail-served industries and this fact plays right into my hands, as I have a

distinct preference to operation and the shunting of freight trains. To this

end, I designed the layout with a number of industrial sidings, all of which

allow me to shunt to my heart’s content. Yes, I do run the occasional DMU

passenger train but, like the prototype, they tend to get in the way of the

freight trains! That last remark may give you a clue to the 1980 - 1985 era that the layout is set in, as I much prefer the BR

Corporate Blue diesels and the colourful Railfreight and Speedlink livery of the freight wagons.

Figure 2 - The main repair shed at the Wagon Repair Depot

was assembled from twelve Airfix/Dapol engine

sheds. The other structures are

scratch-built or kit-bashed.

Before

going any further, I should make it clear that the track plan bears absolutely

no resemblance to the prototype Fort William, but I have tried to capture the flavour of the region by incorporating buildings and

scenery that can (or could) be seen there. I must also confess to slightly

warping history by adopting a failed 19th century scheme that hoped

for a direct line from Glasgow via Fort Augustus and up the Great Glen to Inverness.

This would have meant that the terminus at Fort William would have been at the

end of a short branch-line and this is what I have modelled.

Construction and Scenery

I decided

to paint the back-scene before starting any serious carpentry, as previous

attempts with other layouts had demonstrated the real problems accompanying the

ungainly stretching over wide baseboards. Thus, some forward planning was

required to marry the background into the proposed track plan and the other

major foreground scenery items. But, as this is mainly comprised of rolling

hills and mountains, it was not too difficult. First a coat of graduated

sky-blue colour was applied, followed by the hilly

terrain - painted a bluey, greenish, greyish colour and which

eventually was easily melded into the foreground landscape on the baseboards

(Photos 1, 3 & 6).

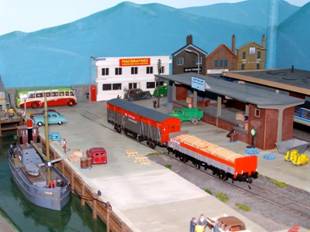

Figure 3 - A busy scene at the Fort William quay, with the High Street in the background and a Clyde Puffer tied up alongside.

When the paint

was dry, I made a start on the baseboards themselves - track-bed 16mm thick MDF

supported by L-Girder framework. A curved fascia board neatens the edges and a

pelmet hides the fluorescent strip lighting.

All the

point-work was built off‑site over Templot

printouts, using ply and rivet construction. For the plain track, I did start

out with the same ply and rivet method, but eventually caved‑in and

resorted to C&L plastic track-bases for the remainder. All of the

track-work is laid over 1/8” thick closed-cell foam strip (as used to lag

pipes) and which was sourced from a plumbers hardware

supply shop.

The

buildings are either scratch-built or heavily kit-bashed, using a variety of

materials (Photo 2). Most of the larger industrial buildings have provision for

wagons to be shunted into or through them. In these cases, they are made

removable to allow the recovery of errant wagons. In fact, wherever possible, I

tend not to fix down any delicate items that are close to the track-work, as

they can then be easily removed to aid track-cleaning, dusting or for the

inevitable repair and maintenance job.

Control and Operation

The layout

was designed for DCC control and runs with a NCE PowerCab,

assisted by a Cab06. The points and signals are operated from lever frames,

with actuation via a wire in a tube. Reflecting the prototype era, the layout

depicts a mixture of semaphore and colour light

signals. The trains themselves are run to a sequence timetable and only when

one arrives at the destination does the next one proceed. Shunting takes place

between the individual trains and progresses at the pace of the individual

operator. No pressure!

To assist

with the shunting, all the rolling-stock is equipped with Kadee

couplers, which I think do not look out of place on modern-image stock but,

most importantly, they work!

Figure 4 - Departmental Laboratory Car No. 20 at the

renewed portion of the main line to the North.

A large

feature of the layout is the Corpach Wagon Repair

Depot (WRD), which is perceived to receive wagons for repair from all over the

region. This means that a variety of freight rolling stock can be seen running

on the layout, many of which would not normally be seen or be required at the

other local industries. The WRD accepts wagons for Heavy, Light or Chassis

repair classification, but they are first put through the Wash Station for

systematic cleaning before they are shunted into the appropriate section of the

Repair Shed and, if required,

moved to the Paint Shop before being finally dispatched back into

service.

Wagon Cards and Waybills

I initially

adopted a card system to facilitate the movement of all the individual wagons

around the layout, from the cassette system, via the Reception Sidings, and on

to all the various industries. Each wagon is assigned its own Wagon Card

(75mm x 50mm), which is equipped with a small pocket. This pocket

enables a range of paper slips (waybills) to be inserted, which in turn directs

the wagons to the appropriate industries for loading or unloading. The fascia

board was equipped with special pockets to hold these wagon cards - indicating

those that were ready for ‘Pick-Up’, ‘Set-Out’ or ‘Hold ‘.

However, whilst this system worked well, in practice I found that it became a

bit cumbersome for an operator to hold a sheaf of these cards, as well as the

hand-controller, an uncoupling tool and also to manipulate the lever-frame. It

therefore really needed a number of small flat desk areas to lay out the cards

and to sort them into the various category piles required for the next shunt.

Figure 5 - The small ex-steam shed is host to a refueling Class 37 and one of the Class 20 allocated to this remote but busy outpost of the NBR.

Figure 6 - The Corpach Station

car park is well filled with tourists and, after viewing the statue of the

local hero, they can take refreshments at the adjacent Corpach

Inn.

To try and

overcome this problem, I have recently implemented a computer software package

that does the same job as the Wagon Cards. This does not mean that I have

broken my golden rule of not allowing a computer into the train room! All I

have to do before each operating session is to print out a single sheet for

each freight train that will run in the next session. These sheets list all the

wagons that are to run in the freight trains, where these wagons are presently

located and the destination they are to be shunted to. Thus, to carry out their

job, each freight train operator is simply equipped with a single sheet of

paper and a pencil behind the ear.

Figure 7 - Class 156 DMU at Fort William Station

platform.

Apart from

the dedicated industrial sidings (Photo 3) that are scattered around the layout

and that can accept only the appropriate wagons and their loads, there is one

other section of track that is busy all the time. You will note that the main

line exits the cassette (from Glasgow) and heads directly north and vanishes

into a cutting and finally disappears under a road bridge. This portion of

track, from the junction to the road bridge, is regarded as being “under

repair” and within the control of the District Engineer. (Photo 4)

Operationally, it means that this section of the main line is regarded simply

as a siding and, as such, is just another industry that requires wagonloads of

spoil, ballast, sleepers, rails, etc.

Stock Control

For what is

a compact layout, the locomotive roster is not huge and, in practice the WHR

played host to a limited range of classes. The freight trains are assigned to

either a Class 26/27 or Class 37, whilst a Class 20 handles local shunting and

trip workings. (Photo 5) The WRD has its own dedicated Class 08.

Passengers

are accommodated in a Class 156 DMU, which trundles back and forth between the

cassette and the Fort William platform and generally tries to get in the way of

the freight trains! (Photo 7) Most of the above equipment is from the LIMA

stable, but an upgrade program is under way and they are gradually being

replaced with suitable Bachmann or Heljan products.

At this point in time, they are all fitted with NCE decoders.

The bulk of

the freight stock is RTR Bachmann or Hornby - suitably re-wheeled - but I have

added a number of kits and a few scratch-built ones as well. (Photo 8) The

majority of the 4‑wheeled stock is compensated, but in recent times I

have been fitting wire-sprung W-Irons, sourced from Bill Bedford or Masokits .

Figure 8 - Among the freight wagons on the layout are

several scratch-built examples. Shown in

the reception sidings is a TOPS FFA container flat, JSA curtain-hooded bogie

steel carrier and PRA clay hopper. The

other wagons are proprietary RTR.

All the

Open wagons can be equipped with easily removable loads, so that only suitable

goods are seen to be loaded at the appropriate industry. Obviously, they are

removed to allow the wagon to run empty, especially if they are deemed to be

heading to or from a session in the repair shop.

Job Satisfaction

So, the layout

is my wee part of Scotland that I have attempted to create on this side of the

world and which allows me to relax and to operate a variety of trains in a

leisurely but methodical manner and, if need be, with invited fellow operators.

All that

remains is for me to mention those who have assisted me over the four years of

the construction. I will not embarrass them by mentioning them by name , but they are mainly members of the BRMA Canberra Area

Group. Thanks to all who helped with such things as creating the Templot track plan, the huge WRD Workshop building, various

trees of assorted shapes and sizes, gluing down and colouring

acres of carpet underfelt to create the grassed areas, soldering the hundreds

of electrical droppers and by generally providing constructive criticism as the

layout progressed. Without their assistance, construction would have taken a

lot longer but, as somebody once remarked, “Och

aye, it is not the arriving but the journey that is important!”

*****