NSW - 0029 - Bridport Southwestern - TCH 121

NSW – 0029 - Layout of the Quarter BRIDPORT SOUTH WESTERN – TCH 121

A joint LSWR-GWR mixed-gauge,

point-to-point shunting layout.

It is built in 4mm scale using EM standards, and incorporates a large

number of mechanically-operating devices. Photos are by the author.

Introduction

This layout

was unashamedly inspired by the, now defunct, 0-gauge layout, “North Yard”,

built by members of the North Shore Railway Modellers Association.

I have

always liked layouts that incorporated interesting operational features, and

North Yard, the layout I had enjoyed operating more than any other, had almost

everything. But, it was a large

cumbersome affair that was the very devil to set up and transport, so I set

myself the task of building a miniature version of it, but one that would, if

anything, incorporate even more working mechanical devices.

Planning

When

planning Bridport South Western, my first

consideration was that it had to be small enough to fit inside my own Toyota

Echo hatchback for transport purposes.

Apart from anything else, I am now getting old, and cannot manage the

back-breaking task of carrying large base boards.

This meant

that it all had to fit onto two 100cm × 55cm base-boards, plus a small

Denny-type fiddle yard.

The second

consideration was that, like North Yard, it had to include a wagon turn table,

loco traverser, wagon tipper and a waterway with a

lifting bridge, but space limitations would not allow a rope-worked incline

that was a feature of North Yard.

Additionally though, it would include a loco turn table, loco coaling

plant with wagon tipper and a working overhead crane for wagon load

trans-shipment. But, then I wanted

something else; something that no one in Australia (as far as I know) had

tried. Yes, mixed broad-gauge/

standard-gauge track.

Theme

The

principal theme for the project was that, like North Yard, it should be a

shunting layout with only occasional passenger trains. The secondary theme was that it should

incorporate a small motive power depot, something that I have always wanted to

model.

Being

already committed to EM-gauge, I decided on mixed 28.0mm/ 18.3mm track, with

EM-gauge standards extrapolated to encompass the 7ft-gauge prototype.

The period

to which the layout could conform had to be 1892 or earlier, as all broad-gauge

was abandoned in this year. I decided to

make it as late as possible.

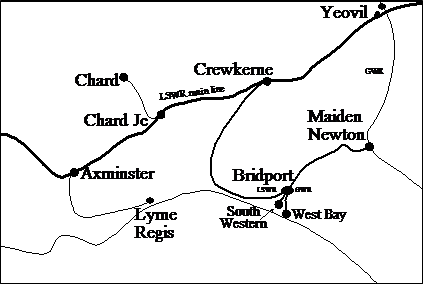

Given the

above requirements, I had no choice but plump for a fictitious location, but,

of course, one that could encompass a might-have-been theme.

In previous

layouts, I had postulated fictitious branches of the LSWR in the Devon or

Dorset counties. So, continue on the

same theme, I plumped for a branch line from the LSWR main line at Crewkerne, through Broadwinsor, Neverbury and Charmouth to the

historic town of Bridport on the Dorset coast. Bridport was, in

reality, serviced by the GWR, so this would give me an excuse for incorporating

mixed-gauge features.

Further, to

justify such a small station area, yet incorporate sizable loco servicing

facilities, I postulated a twig from the main station of Bridport,

to a Harbour near the Brit River estuary.

The area could therefore include the running shed for the main LSWR

station. Thus comparatively-large tender

locos could be seen on the layout without the need for bringing in long trains.

The

broad-gauge side of the equation was that the twig should be of mixed gauge,

laid for transfer-freight purposes.

Locomotives

Given the

period of 1892, my current commitment to the LSWR would be limited to my using

only Adams or Beattie locomotives. As I

already have two Beattie 2-4-0 “Well Tanks”,

an Adams O2 class 0-4-4 tank, an

Adams 415 class 4-4-2 “Radial Tank”, an Adams X2 class 4-4-0 and an Adams A12 class 0-4-2 “Jubilee”, I am well served. All my stud of Drummond locos could not

‘legally’ be used as Drummond did not take office until 1895. No doubt the Drummond locos will be pressed

into service in emergencies though.

If I like

to dream up that through Somerset and Dorset trains from the north could have

used the branch, then I have two S&D locos (a 4-4-0 tender and a 2-4-0 tank) that

could ‘legally’ be used on the layout.

All my

locomotives are scratch built.

Of the GWR

I had nothing, let alone anything broad-gauge, so I built a Gooch 4-4-0 saddle tank, two wagons and a brake

van, which, at the time of writing is all I have to operate with.

Figure 1 - Adam’s “Radial Tank” 4-4-2T No.169 takes coal while “Well Tank” No.329 propels wagons up the coaling ramp.

Rolling Stock

For

occasional passenger working, I have a set of four 4-wheeled LSWR coaches,

although for variety I have a similar number of 6-wheelers.

Standard-gauge

goods stock is almost limitless with a miscellany of wagons, brake vans, horse

boxes and parcels vehicles to choose from.

Most of my

rolling stock is scratch or kit built with about equal numbers of each.

Couplings

At one time

or another, I have tried almost everything, but for the last 25 years I have

standardised on three-link couplings. I

have never been able to come to terms with the disadvantages of automatic

couplings, but now, into my seventies, and with my eyesight going, I have had

find something that would, at least, couple automatically.

Of all the

automatic couplings I have seen described, the one that has inspired me most is

the “Scot Link” type invented by BRMA member Robert Franks and described in TCH-88 in September 2000.

I am using

a simplified version of the Scot Link, which briefly consists of a upturned hook on one wagon that will couple automatically

with a buffer-height transverse bar on another wagon.

The hooks

are made from 10-thou piano

wire, anchored at the far end of the wagon, a-la Alex Jacksons. I will continue to uncouple mainly manually,

which is as simple as pushing downwards on the hook. I will install some permanent magnets for

uncoupling at suitable locations, but I have no intention of incorporating

delayed uncoupling, a system that I have always found to be a nightmare.

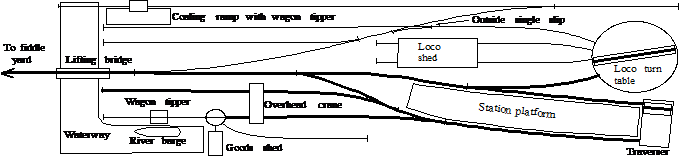

Trackplan

The plan

(as shown below) was designed to cram as much as possible into as small a space

as possible, within the limitations of points no sharper than 4ft radius.

The biggest

space-saver is the loco traverser at the platform end

that saves the length of two sets of points that would be required for a loco

release. This might be unprototypical, but my experience is that if you searched

far enough, you would find such a thing somewhere. The single slip, of course, saves space, and

as it is an outside slip, it saves even more space because a less acute

crossing angle can be used. Outside

slips, although uncommon on the mainlines, are quite

prototypical in goods and loco yards.

Figure 2 - X2 class 4-4-0 No.591 arrives on shed after crossing the lifting bridge.

Baseboards

Baseboards

consist of simple box construction made from 9mm plywood on top of which is

glued a sheet of 12mm Kanite.

Trackwork

All track

and pointwork is constructed by the now-common method

of soldering rail onto sleepers made from printed-circuit board. This is a method I have used exclusively for

the last 40 years.

Chucks

ballast is used, retained with watered-down PVA glue applied with an eye

dropper

Point mechanisms

All points

are operated by mechanical rodding, above the

baseboards, but buried under the track in the kanite. Depending on the distance the rods travel,

some of it is in brass tubing. All rodding is straight, and where it has to turn corners, bell

cranks are used.

Instead of

using points levers to activate the rodding, the rods are connected to Dick Smith slider

switches, which, of course, are used to switch the polarity of the live-frog

points.

Structures

All steel

structures such as the lifting bridge, gantry crane, wagon tippers, coaling

plant, turntables, foot bridge and traverser

are made from printed circuit board (PCB), guillotined up into suitable-sized

plates or strips.

The big

advantage of PCB for structures such as turn tables and moving bridges is that

rail can be soldered directly onto the media and, more to the point, the whole structure can be split in polarity. Thus, sliding or wired pick ups to the

structures may be eliminated as the power can be fed directly through the

structures anchorage points.

Buildings

shells and walls are made from a variety of materials such as printed-circuit

board, cardboard or paddle pop sticks, onto which is glued a veneer of balsa

wood. Simulated stonework is then burnt

into the balsa wood with a soldering iron.

Scenery

Landscaping

is almost non existent, and limited to the few centimetres of space leading

into the fiddle yard. What there is of

it though is built up by the now-almost-universal method of expanded

polystyrene and plaster.

Electrical Wiring

As the

layout is intended for one-man operation only, wiring is relatively

simple. The trackwork

is divided up into suitable sections fed from single-pole on/off switches on

two adjacent mimic panels, one for each baseboard. Thus, connections between

baseboards consists of but two wires only.

Common

return is used on all sections, fed from a grids of

bare-copper wire routed underneath each base board.

Operation

Even though

most (if not all) trains are hauled by tank engines, most locos are turned

between arrival and departure, simply because the viewing public like to see a

turn table operating.

Typical

operating sequences are as follows.

1: Arrival

and departure of a standard-gauge (SG) coal train, which propels its wagons up

the coaling ramp and tips the contents into the coal hopper. The empties are refilled in the fiddle yard.

2: Inward

and outward movements of SG light engines, which are turned coaled and serviced

on shed.

3: Arrival

and departure of a SG passenger train, which will pick up or detach horseboxes

or parcels vans.

4: Arrival

and departure of a broad-gauge (BG) goods train, which will trans-ship loads

between SG wagons using the overhead gantry crane.

5: Arrival

and departure of a SG mixed goods train, which will trans-ship some of its load

between BG wagons, tip the contents of mineral wagons into a river barge; and,

using ropes and poles, shunt wagons into and out of the sidings fed from the

wagon turn table.

Sound Effects

As with my

previous layout “Lulworth Cove”, which still exists

but which I no longer exhibit, I will feature a recorded commentary and

steam-train sound effects. When my

friends and I started this idea more than 20 years ago, we expected everyone

else to follow suit, but (to my knowledge) no one has. It is now 17 years since I have heard sound

effects on a layout, which is when I last exhibited “Lulworth

Cove”.

The Future

No doubt

more broad-gauge rolling stock will be added, such as another locomotive, some

more wagons and maybe a couple of coaches.

It is my

intention to exhibit Bridport South Western twice a

year while my health stays good.

Hopefully the first outing will be at Forestville in March 2009.

Figure 3 - Gooch broad-gauge 4-4-0T “Corsair” waits the road at the signal box. Note the realistic stonework.

Figure 4 - Adams 02 class 0-4-4T No 185 "Alexandra" and Adams A12 class Jubilee 0-4-2 No 652 wait on shed while the modeller admires his own creations.