QLD - 0163 - Princetown - TCH140

Princetown

Twisting sharply and climbing steeply, the branch line to Princetown ran for 10 miles over bleak windswept moors from Yelverton to its terminus at what was the highest station in England, 1,373 feet above sea level. While the line linked two places only 6 miles apart as the crow flies, the sharp curves and gradients as steep as 1 in 40 dictated a speed limit of 20 mph and an average journey time of 41 minutes. After 73 years the last passenger train ran on Saturday 3rd March 1956.

Figure 1 - The display board showing photos of the station and branch line past and present.

Having decided that I wanted to construct and show a layout, my first task was to decide the location and time frame. As I had been modelling the Great Western and early BR Western Region for a number of years and had plenty of rolling stock for this period, then this had to be the time frame and region. I just had to decide on a specific location. I wanted to model a terminus with a turntable and engine shed if possible. I spent over two years looking for the right location and then researching the area. A number of books were purchased and much time spent on the Internet looking at photos and maps. One useful idea that helped me find information was to search eBay with the name “Princetown” which came up with lots of interesting books, magazines, photos, DVDs, train tickets and other memorabilia. The most useful book found on Princetown was Great Western Branch Line Termini Vol 2 by Paul Karau, as it contained not only lots of photos and the story of the station, but also scale drawings of most of the buildings on the site. Once I had settled on Princetown as the location for my layout, I spent a long time drawing plans to make sure I could fit the track in. With a little alteration to the track plan it would fit on to three 1200mm x 800mm baseboards and the bridge would act as a scenic break to the fiddle yard. When discussing the plans with fellow BRMA members it was suggested that to get the right atmosphere it would be good to show part of the line crossing Dartmoor. So I enlarged the layout to show the line rising up through a cutting to terminate at Princetown. One advantage of the new track plan was that I could now also include the head shunt and signal on the other side of the bridge. These same BRMA Members agreed to assist me with the electrics, track work and scenics and also help with operating the layout at shows. Without their help and assistance it would not have been possible to complete Princetown to its present form.

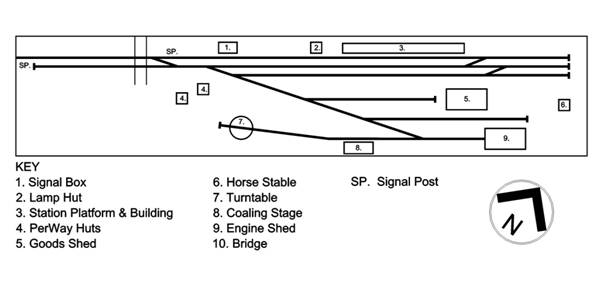

Figure 2 - Princetown station plan showing the extra siding and crossover on the model.

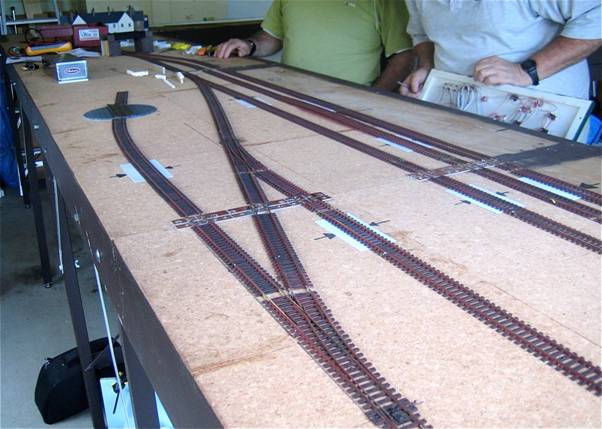

The layout consists of seven baseboards: four of flat top construction and three of the open frame type. Six of the boards are 1200mm long and are designed to bolt together for transportation. The fiddle yard board is 1600mm long and is transported alone. Each board is constructed of 120mm x 12mm timber, with a 8mm ply top covered in cork floor tiles. The boards are joined together by bolts located through steel mudguard washers that are set into rebates on the end of each board. The same holes and bolts are used to bolt the end spacers to the boards for transportation. Boards two and six have two sets of legs and the other boards are attached to these boards. Where possible folding legs are used. All bracing for legs and boards is aluminium, to save on weight. Back scenic boards and lighting along with the main control panel are attached to the back of the front baseboards. In its present form the layout is a U shape, with front and side viewing boards and rear fiddle yard board, the layout measuring 5.0M x 2.6M x 5.0M.

Figure 3 - The front baseboards with electrcal work in progress. The station building will be on the right.

All track work is Peco Code 75 with electrofrog points. As installed, the track plan was as close as possible to the track design as used in the 1930s. However, after the first two shows we attended, it was decided to change this plan slightly and add an extra crossover and siding, which would allow better run-around and give us some extra storage in the yard. At the same time, we extended the fiddle yard board by 450mm and re-aligned the sidings, so that we could store more trains. When I was planning the layout, I had a number of design features and items I wanted to incorporate. These included Tortoise point motors, electro-magnet uncouplers, working signals and auto train control. It would take a whole article to describe the design and installation of these items, so I am including here a few brief points taken from an article written for Harold Fanshawe of Modratec, the full article being available on the Modratec website. When the layout is in auto mode, the train starts in the fiddle yard and the Micro-controller drops the brake relay for the inertia controller. This then turns on the train controller and the train slowly leaves the yard. The Micro-controller then clears the home signal, and the distant signal three seconds later. The train continues almost to the station platform, where it passes over a detector, which tells the Micro-controller to place the distant and home signals to ‘Stop’, and picks up the brake relay, to allow the brake to the inertia controller to slow the train as it arrives into the platform. After a 15 second time delay the starter signal is cleared by the Micro-controller. Then the brake relay is released and the train slowly gathers speed as it leaves the station and heads back down the line to the fiddle yard. When it arrives in the fiddle yard, it passes over another detector, which places the starter signal back to ‘Stop’ and applies the brake to stop the train. After 20 seconds the process will repeat itself. When operating in manual mode, the layout is controlled by two hand-held controllers designed and built by another BRMA Member. The yard controller can be used to shunt the yard while the layout is in either auto or manual mode on the branch line, which ensures that we can keep the layout operating at all times. The main reason for the auto control is that one person at train shows can operate the layout, as it makes it possible both to shunt the yard and run a train on the branch line at the same time.

Figure 4 - View from the front of the layout showing the yard and station building.

Three Ratio semaphore signals are used on the layout: a distant, home and starter signal. However, we found them to be quite fragile, so before our first show I rebuilt them with brass parts. To do this I replaced the plastic pin in the signal arm with brass wire and drilled out the signal post and inserted a brass rod glued in place with Araldite. Fulgurex slow- action point motors operate the signals. We looked at a number of alternatives, including Tortoise and Viessmann motors. However, the Fulgurex motor was decided on, due to the ease of mounting and connecting to the signal. The layout also has a number of ground signals, but, while I have been asked a number of times at shows if they work, at present there are no plans to do this. The signals can be operated both in manual and auto mode, so, over the three years we have been exhibiting Princetown, they would have operated many hundreds, if not thousands of times, with no problems. I have spare signals that can be used to replace a faulty signal, and this can be done in about five minutes due to the plug in design of the signal.

Figure 5 - The open frame quarry board under construction.

Figure 6 - The finished quarry board showing the siding and King Tor Halt.

All the buildings on the layout are scratch built, with the exception of a couple of huts. I was able to use the drawings in Paul Karau’s book for all the station buildings apart from the stable, which is not in the book. I visited Princetown in 2008 while the layout was still being constructed and was able to measure and photograph the stable. As luck would have it, this is the only building still standing on the site. All the buildings are constructed from styrene, with most having Bill Bedford etched brass windows. The rough concrete render finish on the station buildings is achieved with a Dulux paint product called Sandswept Effects, purchased as a sample pot from Bunnings. The tile roofs are all made from manila folders cut into tile strips (as I was shown many years ago). Doors are scratch built or made as resin castings from door masters made by myself. All the structures, including the bridge, are not fixed to the layout and are removed when the layout is dismantled for transportation. The quarry and the hills are built from foam and then covered in Chux wipes coated in plaster. The hills at the rear of the baseboards are built on MDF bases, so that when the layout is erected they can just be dropped into place. The quarry and rail cutting were sculptured along with the large rock outcrops; the other smaller rocks were made in a Woodland Scenic’s rock mould and stuck and plastered into place. As the rocky outcrops are such a feature on Dartmoor, a lot of time was spent getting the granite rock colour as close as we could. The large grass areas on the layout are made of carpet underlay and scatter material, while the long grass tufts came from Mininatur. As the layout is set in early winter, I made the few deciduous trees and then started on the pine trees. After making around six I realised I needed over 120 to complete the job, so gave up and purchased bulk packs of spruce trees from Bachmann, thus retaining my sanity. We also populated the station area with more people than I am sure would normally have been at Princetown Railway Station. Almost 100 sheep, ponies, rabbits and various other animals can also be seen on the layout. My wife painted the back scenes and made the curtains for the layout, while our daughter designed and produced the layout name boards in GWR livery.

Figure 7 - A pannier tank loco on the turntable in the yard.

Figure 8 - Board number one under construction showing a trial location of the goods and loco sheds.

Figure 9 - The goods shed with the long siding in the foreground.

Due to the fact that only six or seven trains a day operated to and from Princetown, we realised we could not operate a prototypical timetable. So we drew up a list of known train movements and then added a few more that we thought would look right. This gave us 15 train movements in total. As some of these movements involve shunting the yard, it can take quite a while to complete them all. Our main aim is to have a train moving on the layout most of the time. It can involve a loco running around its train, turning on the turntable, or just shunting the yard or quarry. We believe it is important to entertain the paying public. With the rolling stock we have available, we normally run with GWR stock on one day and BR the next. One advantage with the movement of freight at Princetown is that, while the village itself is quite small in size, the fact that Dartmoor Prison is located in the village ensured that large volumes of general van freight and coal wagons for the prison gas works passed through the station.

Figure 10 - The loco shed with the goods shed in the background.

In the time frame we are operating Princetown, only two types of loco were used on the branch: GWR 44XX and 45XX 2-6-2 tank engines. 19XX 0-6-0 class saddle and pannier tanks fitted with snowploughs were also frequently used to clear the line during the winter months. These small locos were the only engines able to be turned on the small turntables at Princetown and Yelverton. A decision was taken quite early on in the building of Princetown, that we would run other locos than these, as long as they looked right. This may not please some purists, but it does enable us to have a good variety of locos in operation on the layout. All stock has been fitted with Kadee couplers to enable hands-free uncoupling when shunting and also to enable locos to run around trains in the station.

Figure 11 - A 45xx tank loco with a two coach train approaching the station and a 27xx loco fitted with snow plough in the head shunt.

One aspect of the layout that attracts a lot of interest is the small turntable in the yard at Princetown. I have lost count of the number of times we have been asked how it works and where one can be purchased. The turntable was constructed from a Peco HO kit and the floor of a Peco loco lift, the rest being built from plastic and brass sheet. An Expo Clearbox motor with a variable gearbox powers the turntable. This gearbox enables the ratio of the gears to be altered to provide very slow turning of the loco on the turntable.

There are still a couple of jobs to do on the layout; one of which is the installation of point rodding. All the components have been purchased, but as yet work has not commenced on the building and installation. I also intend to weather the ballast on the running line. While it has toned down over the last couple of years, it still needs to be weathered. We are also in the process of weathering all rolling stock. Having completed all wagons and coaches, a start has now been made on the locos.

Figure 12 - The bridge leading to the moor at the station approach.

An item I wanted to include in the layout was a board with photos of Princetown past and present, along with maps, closure notice, GWR train ticket and other information. This board attaches to the end of the last scenic backboard and has proved to be a big hit with show visitors, with many people stopping to look and then compare the photos with the layout. We have had a lot of questions about the area and even welcomed two senior visitors who had actually travelled on the line!