VIC - 0639 - Sarum Bridge - TCH 146

VIC – 0639 – Layout of the Quarter - Sarum Bridge – TCH 146

Sarum

Bridge is a little T Gauge exhibition layout I built during the first

half of 2014. This article describes it in its more-or-less complete form, as

shown at AMRA Caulfield in August 2014.

I have been

intrigued by the possibilities of Eishindo’s T Gauge

system ever since it first appeared a few years ago, but the product range was

very limited and there were enough technical problems that it didn’t seem worth

trying. A combination of four things pushed me over the edge: new

second-generation mechanisms that could actually run slowly, a very nice RTR

HST set, a decent range of hobbyist-produced 3D printed body shells in British

outline, and seeing Orbost - a large layout in a

totally different class from the typical T micro-layout.

It was

clear from the start that T is not a general-purpose scale - there are many

things you simply cannot do in it. Even reversing with a string of 4-wheel

wagons is better imagined than attempted. A few experiments also showed that

the points weren’t reliable enough for any sort of automatic running, especially

with 4 wheel wagons. This left some sort of simple roundy-roundy

design as the only viable option.

Background to T Gauge

I used T

Gauge flexi track throughout, but here there are some significant differences

from larger scales. The rails are steel, and the track tends to twist like a

corkscrew as soon as it is removed from its packing tube. This gets worse when

the track is bent into a curve. After a few experiments, I ended up gluing the

track down using superglue. Straight sections were aligned against a steel

rule, and glued about 18” at a time, pressing down with fingers and a wooden

block (moving them constantly to ensure they didn’t stick!). Curves were done

the same way, judging position by eye. These were not as successful, the short

drying time for the glue not leaving enough time to lay them properly parallel.

The rail

joiners are pairs of conventional fishplates mounted on fixed sections of six

sleepers. Each brass fishplate has a lug on the underside that can be bent down

and soldered to for power feeds. The track cuts easily with Xuron

cutters, and I also used these to cut rail breaks. A quick experiment with a

Dremel showed that this was not the way to go - sparks and bits everywhere -

the rail and sleepers are not strong enough to hold together under that sort of

stress.

Many people

use the set-track range rather than flexi track. This has integral ballast but

comes in very short pieces, so you get lots and lots of rail joints. The points

are manual only and quite crude, but probably OK if not using 4 wheel wagons or

automation.

T Gauge

rolling stock is quite conventional in many ways, but has its own

peculiarities. Unusual aspects are magnetised pickup

and driven wheels for use with the steel rail; instead of the usual wheel/axle

box arrangement the wheel faces have hollows and the axle boxes have matching

lugs or dimples. This makes for a lot of

friction, so when combined with the limited hauling power of the locos it

really does limit maximum train lengths. Rerailing stock is surprisingly easy,

although it pays to ensure that there is a nice long unobstructed section of

straight track available (I use the viaduct). Couplers are very similar to N,

but a tight fit - pairs generally have to be squeezed together with tweezers to

ensure that vehicles are not lifted off the track. That is the trickiest part

of setting up a train.

Electrics

are just basic DC but running on 4.5V rather than 12V. For some reason, Eishindo chose to reverse the polarity - unlike all larger

scales which have the right rail positive, T has the left rail positive. The

track-to-wheels electrical pickup area is one of T’s problem areas, since this

is very, very sensitive to dirty wheels and track. For serious operation, all

trains should have at least two motor units (a full HST rake has 3). I chose to

permanently couple and wire together pairs of locos for my paper and goods

trains. This worked very well - over a two-day exhibition of continuous

stop/start running, I never had a stall and never had to clean the track (except

for my little one-motor DMU backup train). The locos had only a basic

superficial wheel clean overnight.

The basic

train set controller is a battery/mains PWM design, which also comes with two

optical sensors for auto-reverse. This allows you to set up basic shuttle,

station stop or station-stop-and-reverse systems straight out of the box. Alas,

this uses a full-speed / dead-stop approach, even though the computer-based

controller would be perfectly capable of smooth stops and starts.

The RTR

range consists of a decent collection of Japanese multiple unit stock, plus

very nice ICE and HST sets. These even have directional lighting. There are

also a number of different sizes of powered chassis, but all Bo-Bo bogie types.

They also have a variable-length coach chassis that you cut to length with a

pair of Xuron cutters and then fit the second bogie

into one of about ten positions. There is a quite a wide selection of

UK-outline 3D printed body shells available from different modellers

at Shapeways. The last time I looked, this included

classes 66, 55, 42, 25, 24, 08, GWR passenger and parcels railcars, A3, A4, C1,

Merchant Navy, Pannier, Jinty and Saddle-tanks, four

types of BR Mk1, suburban coaches, Siphon Gs and a good mix of generic

4-wheelers. There are also a handful of US and European prototypes, but the UK

is very well supported.

The only

local supplier I know of is Hobbies Plus down in Gippsland, who has a decent

range of track plus a few other oddments.

The main T

gauge supplier is undoubtedly tgauge.com (Alan Ramsay Models) in Edinburgh, and

the HST is proprietary to them. Service and response time is good, postage

costs not so good.

The Layout

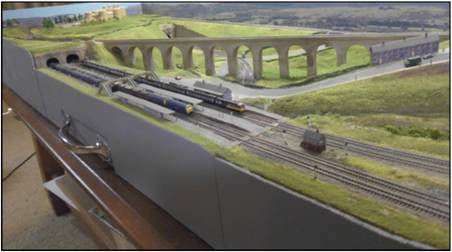

The main

theme and inspiration for the layout was wanting to see a full length HST

crossing a long viaduct. This in turn really implied a main line setting, so

requiring either a double track or dog-bone. After a bit of thought, I settled

on a medium-sized wrapped dog-bone design, configured as an automatic

three-train tail chaser to provide a decent amount of running variety. Three

trains implied at least four block sections, so I decided to put in a four

platform station as well, with all stops performed at the platforms. Since this

would be where most of the visual activity occurred, this needed to be right at

the front of the layout.

The final

layout size was arbitrarily chosen as 4’8.5” x 1’8” (I like round numbers), or

approximately 1.5m x 0.5m. The OO equivalent would be 28’ x 10’. The dog-bone

is tightly wrapped so as to traverse the length of the board five times. The

total track length is 16m, equating to 4 miles or 7 km. With this type of layout, I am willing to

have one 180-degree curve visible at each end of the layout, but the design

required two plus a balloon loop each, so the tracks are effectively on three

levels. The maximum gradient is 1 in 30 on the back straight, with a minimum

visible curve radius of 7.5” (equivalent to 45” in OO).

Baseboard

construction is conventional, with a complete 3mm ply surface on a pine frame,

with a separate 3mm ply trackbed above this. No legs

are fitted - the layout is designed to sit on a table. Adequate clearance for

trains, fingers and track cleaners meant a minimum vertical clearance of 1”,

with access from the sides and two removable hilltops.

The automation

is handled by a PIC microcontroller (small computer). This reads eight optical

sensors (LDRs - Light Dependant Resistors), sited at each end of each of the

four platforms. One of each pair is a slowdown warning; the other is the stop

sensor. This computer handles all the block and signal logic, sending speed

commands to the speed control computer and driving all the signals directly.

The main control is a 4-position rotary switch, selecting stop, manual

(single-train train-set mode), auto1 (full block operation) and auto2 (full

block operation with the odd extra station stop). The speed control computer

provides 4 PWM controllers with inertia and overload detection. This handles

starts and stops.

The signals

are obsolete GWR searchlight types, each just a piece of optic fiber bent over

with a washer added to make a signal head, connected to multi-colour LEDs under the baseboard. The layout is fully signalled according to GWR practice, with each platform

having starter, home and distant signals. Three of these would be in the

tunnels, so only 9 are actually fitted. Two more signals protect the level

crossing.

The level

crossing works, with the mechanical gates driven directly by four cheap servos.

Another small computer handles this task according to instructions from the

main signal computer. The gates are pieces of clear plastic or acetate with the

timbers scribed on and painted. These are quite strong, and have on occasions

been hit by trains or vice versa.

The roads

are a linear motor product by IDL motors. Each oval track consists of about 230

coils on a double-sided circuit board. These are driven in sequence by IDL’s

control box, and effectively form a magnetic conveyor belt. Road vehicles all

have two or four magnets underneath to maintain directional stability. I have

added an extra layer of control to join the two tracks into a figure 8, switch

vehicles back and forth between them, pause them for random intervals in a

hidden section of one track (a fiddle yard!), handle collision avoidance, etc. The

supplied buses were to correct scale for T so I simply repainted them; the cars

were grossly overscale, so I transferred their magnets to proper scale T gauge

cars.

The viaduct

is a piece of pine timber, the arches cut with a hole saw and the pillars then

cut to match, with the whole thing faced by plasticard

stone walling. Tunnels and other civil engineering are just the same simple

stone plasticard cutouts stuck onto a plywood

foundation.

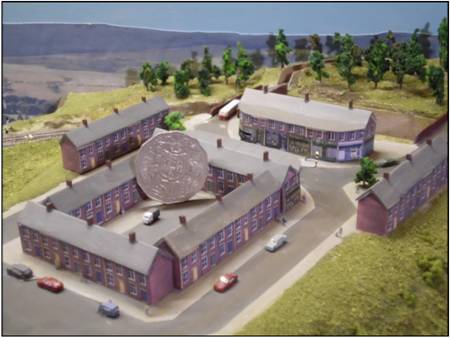

The

buildings are very crude models, but look reasonable at normal viewing

distance. They are basically just DIY card/paper kits. I searched the web for

suitable pictures (mostly of a block of OO terrace houses), then used Paint and

GIMP to edit these into sides that were stuck onto a suitably-sized block of

balsa. Roofs are Plastruct L-girders with styrene

strip for chimneys. The footbridge is made of plastruct

U-channel. Peco track pins make good station lights. Fences are etched brass

parts for ships’ railings, people are etched brass airline passengers. The

castle is a clay mantelpiece ornament of Conwy Castle

from Lilliput Lane.

Summary

T Gauge has

some major limitations, and is certainly not a general-purpose scale, but it really

is possible to build a decent and reliable British layout if you work to its

strengths. That basically means doing a display/exhibition or coffee table

style of layout.

Modelling

in T required learning some new techniques, but was significantly easier than

expected. I have often heard people say that it is too small, and that they

couldn’t work at that level of detail. I find that that is something of a furphy - a typical 12” viewing distance equates to 150m, so

you can get away with quite crude models. Given the amount of detail expected

with larger scale models, I find that those larger scale ones actually require

more fiddliness per square centimeter!

More

information, pictures and videos can be found at

-

http://modelrailmusings.weebly.com/

-

or by searching for Sarum Bridge in Google or

YouTube.